Tool and tool offset

During program creation for the workpiece machining, you do not have to take tool lengths or

cutting radius into consideration. You program the workpiece dimensions directly, e.g.

according to the drawing.

The tool data must be entered separately in a special data area.

In the program, you will merely call the required tool with its offset data. The control system

performs the required path compensations based on this data to create the described

workpiece.

See the following illustration for machining a workpiece with different tool dimensions

Tool T (turning)

The tool selection takes place when the T word is programmed. Whether this is a tool

change or only a preselection is defined in the machine data:

● A tool change (tool call) takes place directly with the T word (e.g. typical for tool turrets on

turning machines)

or

● The change takes place after the preselection with the T word by an additional instruction

M6.

Note:

If a certain tool was activated, it remains stored as an active tool even beyond the end of

the program and after switching off / switching on the control system.

If you change a tool manually, input the change also in the control system so that the

control system 'knows' the correct tool. For example, you can start a block with the new T

word in MDA mode

Programming example:

Tool change without M6

N10 T1

N20 T3

N30 T2

N40 T6

N50 T7

N60 T5

N70 T10

N80 M30

Tool offset number D (turning):

It is possible to assign 1 to 9 data fields with different tool offset blocks (for multiple cutting

edges) to a specific tool. If a special cutting edge is required, then it can be programmed

using D and the appropriate number.

If a D word is not written, D1 is automatically effective.

If D0 is programmed, the offsets for the tool are ineffective.

Programming

D-Tool offset number: 1 ... 10, D0: No offsets active!

A maximum of 64 data fields (D numbers) for tool offset blocks can be stored simultaneously

in the control system

Tool length compensations become effective immediately when the tool is active; when no D

number was programmed with the values of D1.

The compensation is retracted with the first programmed traversing of the associated length

compensation axis.

A tool radius compensation must also be activated by G41/G42.

Programming example

Tool change:

N10 T1 ; Tool 1 is activated with the associated D1

N20 G0 X100 ; The length offset compensation is overlaid here

N30 Z100

N40 T4 D2 ; Load tool 4, D2 from T4 is active

N50 X50 Z50

N60 G0 Z62

N70 D1 ; D1 for tool 4 active, only cutting edge changed

N80 M30

Contents of a compensation memory

● Geometrical dimensions: Length, radius.

They consist of several components (geometry, wear). The control takes into account the

components to obtain a resulting dimension (e.g. overall length 1, total radius). The

respective overall dimension becomes active when the offset memory is activated.

The way in which these values are computed in the axes is determined by the tool type

and the current plane G17, G18, G19.

● Tool type

The tool type (drill or turning tool) determines which geometry data are required and how

they will be calculated.

● Cutting edge position

For the "turning tool" tool type, you must also enter the cutting edge position.

The following figures provide information on the required tool parameters for the respective

tool type.

See the following illustration for compensations for turning tool with tool radius

compensation

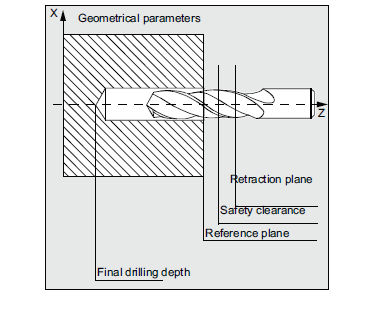

See the following illustration for effect of the compensation for the drill:

Center hole:

Switch to G17 for application of a center hole. This makes the length compensation take

effect for the drill in the Z axis. After drilling, the normal compensation for turning tools takes

effect again with G18.

Programming example:

N10 T3 D1 ;Drill

N20 G17 G1 F1 Z0 M3 S100 ; Tool length offset effective in Z axis

N30 Z-15

N40 G18 M30

Selecting the tool radius compensation: G41, G42:

A tool with a corresponding D number must be active. The tool radius offset (cutting edge

radius offset) is activated by G41/G42. The controller automatically calculates the required

equidistant tool paths for the programmed contour for the respective current tool radius.

G18 must be active.

See the following illustration for tool radius compensation (cutter radius compensation):

Programming

G41 X... Z... ; Tool radius compensation left of contour

G42 X... Z... ; Tool radius compensation right of contour

Remark: The selection can only be made for linear interpolation (G0, G1).

Program both axes. If you only specify one axis, the second axis is automatically completed

with the last programmed value.

See the following illustration for compensation to the right/left of the contour

Starting the compensation:

The tool approaches the contour on a straight line and positions itself vertically to the path

tangent in the starting point of the contour.

Select the start point so as to ensure collision-free traversing.

See the following illustration for start of the tool radius compensation with the example G42

The tool tip goes around the left of the workpiece when the tool runs clockwise using G41;

The tool tip goes around the right of the workpiece when the tool runs counter-clockwise

using G42.

Note:

As a rule, the block with G41/G42 is followed by the block with the workpiece contour.

However, the contour description may be interrupted by an intervening block that does not

contain information for the contour path, e.g. only M command.

Programming example:

N10 T4 D1 M3 S1000 F0.15

N20 G0 X0 Z0 ; P0 - starting point

N30 G1 G42 X50 Z50 ; Selection right of contour, P1

N40 X0 Z0 G40 G1 ; Starting contour, circle or straight line

N50 M30

Tool radius compensation OFF: G40

The compensation mode (G41/G42) is deselected with G40. G40 is also the switch-on

position at the beginning of the program.

The tool ends the block before G40 in the normal end position (compensation vector vertical

to the tangent in the end point); independently of the start angle.

If G40 is active, the reference point is the tool tip. The tool tip then travels to the programmed

point upon deselection.

Always select the end point of the G40 block such that collision-free traversing is

guaranteed.

Programming

G40 X... Z... ; Tool radius compensation OFF

Remark: The compensation mode can only be deselected with linear interpolation (G0, G1).

Program both axes. If you only specify one axis, the second axis is automatically completed

with the last programmed value.

See the following illustration for ending the tool radius compensation with G40:

Programming example

N10 T4 D1 M3 S1000 F0.1

N20 G0 X50 Z50

N30 G1 G42 X30 Z40

N40 G2 X20 Z20 R15

N50 G1 X10 Z10

N60 G40 G1 X0 Z0 ;Last block on the contour, circle or straight line, P1

N70 M30 ;Switch off tool radius compensation,P2

Example of tool radius compensation (turning):

See the following example of tool radius compensation, cutting edge radius shown

magnified:

Programming example:

N1 ; Contour cut

N2 T1 ; Tool 1 with offset D1

N10 DIAMOF F0.15 S1000 M3 ; Radius dimension, technological values

N15 G54 G0 G90 X100 Z15

N20 X0 Z6

N30 G1 G42 G451 X0 Z0 ; Start compensation mode

N40 G91 X20 CHF=(5* 1.1223 ) ; Insert chamfer, 30 degrees

N50 Z-25

N60 X10 Z-30

N70 Z-8

N80 G3 X20 Z-20 CR=20

N90 G1 Z-20

N95 X5

N100 Z-25

N110 G40 G0 G90 X100 ; Terminate compensation mode

N120 M2

cutting radius into consideration. You program the workpiece dimensions directly, e.g.

according to the drawing.

The tool data must be entered separately in a special data area.

In the program, you will merely call the required tool with its offset data. The control system

performs the required path compensations based on this data to create the described

workpiece.

See the following illustration for machining a workpiece with different tool dimensions

Tool T (turning)

The tool selection takes place when the T word is programmed. Whether this is a tool

change or only a preselection is defined in the machine data:

● A tool change (tool call) takes place directly with the T word (e.g. typical for tool turrets on

turning machines)

or

● The change takes place after the preselection with the T word by an additional instruction

M6.

Note:

If a certain tool was activated, it remains stored as an active tool even beyond the end of

the program and after switching off / switching on the control system.

If you change a tool manually, input the change also in the control system so that the

control system 'knows' the correct tool. For example, you can start a block with the new T

word in MDA mode

Programming example:

Tool change without M6

N10 T1

N20 T3

N30 T2

N40 T6

N50 T7

N60 T5

N70 T10

N80 M30

Tool offset number D (turning):

It is possible to assign 1 to 9 data fields with different tool offset blocks (for multiple cutting

edges) to a specific tool. If a special cutting edge is required, then it can be programmed

using D and the appropriate number.

If a D word is not written, D1 is automatically effective.

If D0 is programmed, the offsets for the tool are ineffective.

Programming

D-Tool offset number: 1 ... 10, D0: No offsets active!

A maximum of 64 data fields (D numbers) for tool offset blocks can be stored simultaneously

in the control system

Tool length compensations become effective immediately when the tool is active; when no D

number was programmed with the values of D1.

The compensation is retracted with the first programmed traversing of the associated length

compensation axis.

A tool radius compensation must also be activated by G41/G42.

Programming example

Tool change:

N10 T1 ; Tool 1 is activated with the associated D1

N20 G0 X100 ; The length offset compensation is overlaid here

N30 Z100

N40 T4 D2 ; Load tool 4, D2 from T4 is active

N50 X50 Z50

N60 G0 Z62

N70 D1 ; D1 for tool 4 active, only cutting edge changed

N80 M30

Contents of a compensation memory

● Geometrical dimensions: Length, radius.

They consist of several components (geometry, wear). The control takes into account the

components to obtain a resulting dimension (e.g. overall length 1, total radius). The

respective overall dimension becomes active when the offset memory is activated.

The way in which these values are computed in the axes is determined by the tool type

and the current plane G17, G18, G19.

● Tool type

The tool type (drill or turning tool) determines which geometry data are required and how

they will be calculated.

● Cutting edge position

For the "turning tool" tool type, you must also enter the cutting edge position.

The following figures provide information on the required tool parameters for the respective

tool type.

See the following illustration for compensations for turning tool with tool radius

compensation

See the following illustration for effect of the compensation for the drill:

Center hole:

Switch to G17 for application of a center hole. This makes the length compensation take

effect for the drill in the Z axis. After drilling, the normal compensation for turning tools takes

effect again with G18.

Programming example:

N10 T3 D1 ;Drill

N20 G17 G1 F1 Z0 M3 S100 ; Tool length offset effective in Z axis

N30 Z-15

N40 G18 M30

Selecting the tool radius compensation: G41, G42:

A tool with a corresponding D number must be active. The tool radius offset (cutting edge

radius offset) is activated by G41/G42. The controller automatically calculates the required

equidistant tool paths for the programmed contour for the respective current tool radius.

G18 must be active.

See the following illustration for tool radius compensation (cutter radius compensation):

Programming

G41 X... Z... ; Tool radius compensation left of contour

G42 X... Z... ; Tool radius compensation right of contour

Remark: The selection can only be made for linear interpolation (G0, G1).

Program both axes. If you only specify one axis, the second axis is automatically completed

with the last programmed value.

See the following illustration for compensation to the right/left of the contour

Starting the compensation:

The tool approaches the contour on a straight line and positions itself vertically to the path

tangent in the starting point of the contour.

Select the start point so as to ensure collision-free traversing.

See the following illustration for start of the tool radius compensation with the example G42

The tool tip goes around the left of the workpiece when the tool runs clockwise using G41;

The tool tip goes around the right of the workpiece when the tool runs counter-clockwise

using G42.

Note:

As a rule, the block with G41/G42 is followed by the block with the workpiece contour.

However, the contour description may be interrupted by an intervening block that does not

contain information for the contour path, e.g. only M command.

Programming example:

N10 T4 D1 M3 S1000 F0.15

N20 G0 X0 Z0 ; P0 - starting point

N30 G1 G42 X50 Z50 ; Selection right of contour, P1

N40 X0 Z0 G40 G1 ; Starting contour, circle or straight line

N50 M30

Tool radius compensation OFF: G40

The compensation mode (G41/G42) is deselected with G40. G40 is also the switch-on

position at the beginning of the program.

The tool ends the block before G40 in the normal end position (compensation vector vertical

to the tangent in the end point); independently of the start angle.

If G40 is active, the reference point is the tool tip. The tool tip then travels to the programmed

point upon deselection.

Always select the end point of the G40 block such that collision-free traversing is

guaranteed.

Programming

G40 X... Z... ; Tool radius compensation OFF

Remark: The compensation mode can only be deselected with linear interpolation (G0, G1).

Program both axes. If you only specify one axis, the second axis is automatically completed

with the last programmed value.

See the following illustration for ending the tool radius compensation with G40:

Programming example

N10 T4 D1 M3 S1000 F0.1

N20 G0 X50 Z50

N30 G1 G42 X30 Z40

N40 G2 X20 Z20 R15

N50 G1 X10 Z10

N60 G40 G1 X0 Z0 ;Last block on the contour, circle or straight line, P1

N70 M30 ;Switch off tool radius compensation,P2

Example of tool radius compensation (turning):

See the following example of tool radius compensation, cutting edge radius shown

magnified:

Programming example:

N1 ; Contour cut

N2 T1 ; Tool 1 with offset D1

N10 DIAMOF F0.15 S1000 M3 ; Radius dimension, technological values

N15 G54 G0 G90 X100 Z15

N20 X0 Z6

N30 G1 G42 G451 X0 Z0 ; Start compensation mode

N40 G91 X20 CHF=(5* 1.1223 ) ; Insert chamfer, 30 degrees

N50 Z-25

N60 X10 Z-30

N70 Z-8

N80 G3 X20 Z-20 CR=20

N90 G1 Z-20

N95 X5

N100 Z-25

N110 G40 G0 G90 X100 ; Terminate compensation mode

N120 M2

Comments

Post a Comment