Elements of CNC

A CNC system consists of three basic components

1) part program

2) Machine control unit(MCU)

3) Machine tool(lathe,drill press,milling machine)

Define Part Program

The part program is details set of commands to be followed by the machine tool.each command specifies in the Cartesian coordinate system(xyz) or motion(work piece travel or cutting piece travel), machine parameters on/off functions.part programmers should be well versed with machine tool,maching process,effects of process variables,and Limitations of CNC controls.the part program is written manually or by using computer assisted language such as APT(automated programming tool).

Machine control unit

The machine control unit is a micro computer that stores the program and executes the commands into action by the machine tool.the MCU consists of two main units.

1)DPU(data processing unit)

2)CLU(control loop unit)

DPU

The DPU software includes control system software,caluclations algorithms,translation software that converts the part program into a usable format for the MCU ,inter platoon algorithm to achieve smooth motion of the cutter , editing of the program

The DPU process the data from the part program and provides into the CLU which operates the drives attached to the machine lead screws and receives feedback signal on the actual position and velocity of each one of the axes.a driver and a feedback device are attached to the lead screw. The CLU consists of the circuits for position and velocity control loops,deceleration and backlash take up.function controls such as spindle on/off.

Machine tool

The machine tool could be one of the following

1)Lathe

2) Milling Machine

3)Laser

4)Plasma

5) Coordinate measuring machine

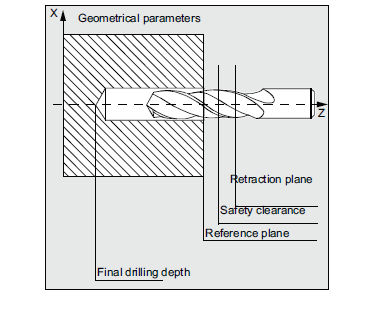

The above figure shows that right-hand coordinate system is used to describe the motions of machine tool.there are three linear axis(xyz)three rotational axes(I,j, k)and other axes such as tilt(°)are possible.

1) part program

2) Machine control unit(MCU)

3) Machine tool(lathe,drill press,milling machine)

Define Part Program

The part program is details set of commands to be followed by the machine tool.each command specifies in the Cartesian coordinate system(xyz) or motion(work piece travel or cutting piece travel), machine parameters on/off functions.part programmers should be well versed with machine tool,maching process,effects of process variables,and Limitations of CNC controls.the part program is written manually or by using computer assisted language such as APT(automated programming tool).

Machine control unit

The machine control unit is a micro computer that stores the program and executes the commands into action by the machine tool.the MCU consists of two main units.

1)DPU(data processing unit)

2)CLU(control loop unit)

DPU

The DPU software includes control system software,caluclations algorithms,translation software that converts the part program into a usable format for the MCU ,inter platoon algorithm to achieve smooth motion of the cutter , editing of the program

The DPU process the data from the part program and provides into the CLU which operates the drives attached to the machine lead screws and receives feedback signal on the actual position and velocity of each one of the axes.a driver and a feedback device are attached to the lead screw. The CLU consists of the circuits for position and velocity control loops,deceleration and backlash take up.function controls such as spindle on/off.

Machine tool

The machine tool could be one of the following

1)Lathe

2) Milling Machine

3)Laser

4)Plasma

5) Coordinate measuring machine

Comments

Post a Comment