| G-FUNCTIONS |

| G00-Positioning (rapid traverse) |

| G01-01 Linear interpolation (cutting

feed) . |

| G02-Circular interpolation CW |

| G03-Circular interpolation CCW |

| G04-Dwell |

| G07 - SIN interpolation (designation of

virtual axis) |

| G09- Exact stop check |

| G10 -Offset amount and work zero point

offset amount setting |

| G17- Designation of X-Y plane |

| G18-

Designation of Z-X plane |

| G19 -Designation of Y-Z plane |

| G20- Inch input |

| G21- Metric input; |

| G22-

Stored stroke,limit,ON |

| G23 -Stored'--s troke"- limit OFF |

| G27- Return to reference paint |

| G28- Return to reference-pant |

| G29- Return from reference point |

| G30- Return to 2nd reference point 4 |

| G31-Skip function |

| G40- Tool diameter compensation cancel |

| G41- Tool diameter compensation to left |

| G42- Tool diameter compensation to right |

| G43 -Tool length compensation |

| G44-

Tool length compensation |

| G49- Tool length compensation cancel |

| G45- Tool offset expansion |

| G46-

Tool offset reduction |

| G47- Tool offset double expansion |

| G48- Tool offset double reduction |

| G50 -11 Scaling cancel |

G51 -Scaling

G code

Group Function |

| G52-Local coordinate system setting |

| G53- Machine coordinate system selection |

| G54- Work coordinate system 1 selection |

| G55-

Work coordinate system 2 selection |

| G56- Work coordinate system 3 selection |

| G57- Work coordinate system 4 selection |

| G58 -Work coordinate system 5 selection |

| G59- Work coordinate system .6 selection |

| G60-

One directional positioning |

| G61 -Exact stop check mode |

| G63- Tapping mode |

| G64- Continuous cutting mode |

| G65-

Macro call |

| G66-

Macro modal call A |

| G67- C Macro modal call cancel |

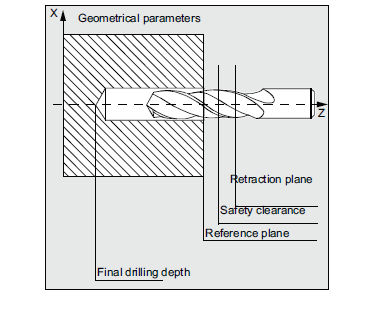

| G73 -Peck dril ling cycle |

| G74 -Reverse tapping cycle |

| G76-Fine boring |

| G80-Canned cycle cancel |

| G81-Dr illing cycle, spot boring |

| G82- Drilling cycle, counter boring |

| G83-

Peck drilling cycle |

| G84- Tapping cycle |

| G85 -Boring cycle |

| G86- IBoring cyc le |

| G87-Back boring cycle |

| G88 -Boring cycle |

| G89 -Boring cycle |

| G90- Absolute programming |

| G91 -Incremental programming |

| G92-Programming of absolute zero point |

| G98- Initial level return (canned cycle) |

| G99- point level return (canned cycle) |

| G501-Programmable mirror image cancel |

G511- Programmable mirror image

M-FUNCTIONS |

|

Comments

Post a Comment